Services

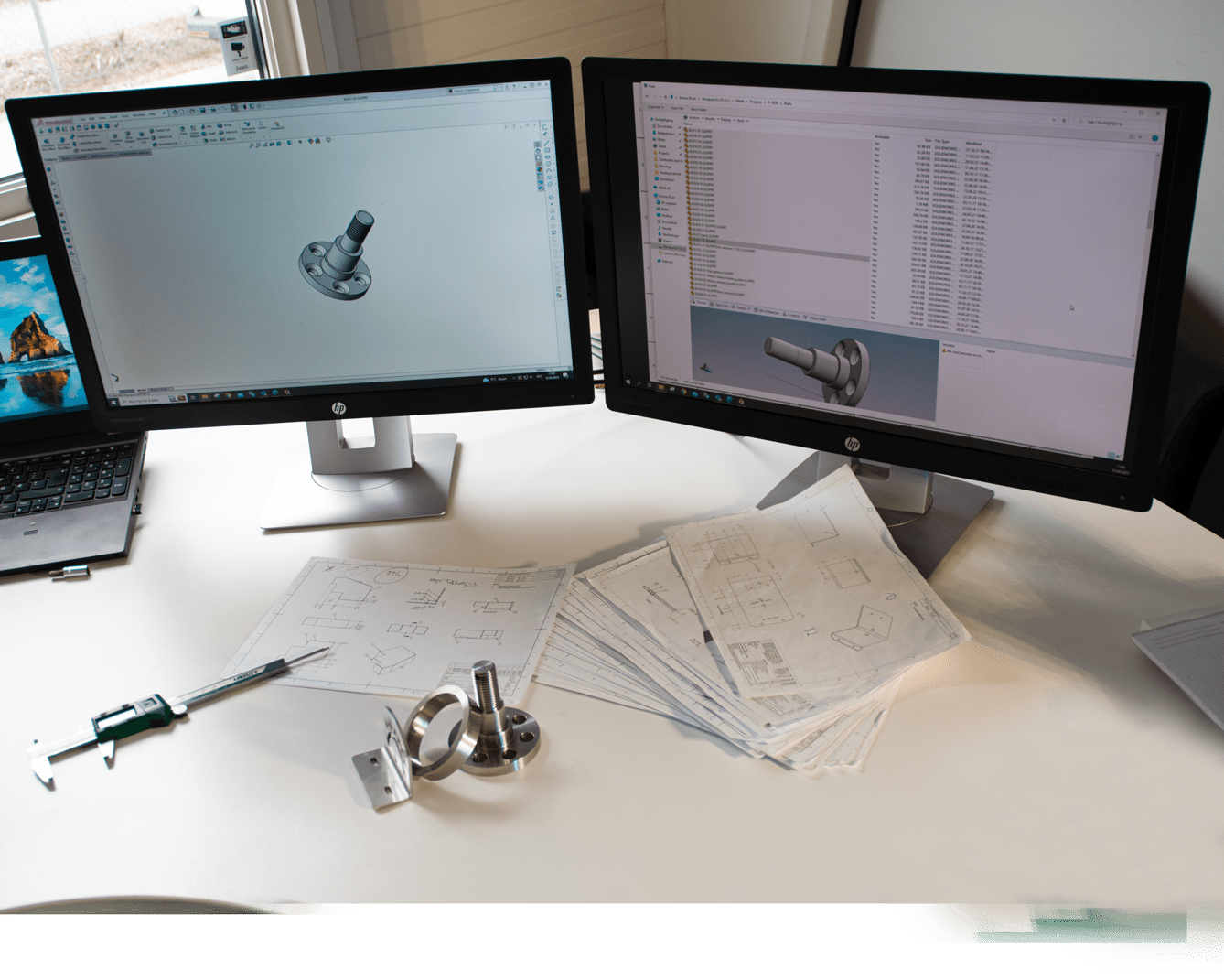

SolidWorks 3D Design

EstNor Steel provides the most cost-effective, top-notch solutions for all your unique 3D design needs. We can quickly generate 2D drawings or 3D models. We use the latest 3D SolidWorks Software, guaranteeing transparent and seamless project delivery.

- Structure Systems and Sheet Metal- have new enhancements in 2023 that enable smoother design-to-manufacturing workflows and speed up tedious tasks

- Assemblies-See how you can increase productivity, design more compelling products, and be more cost-effective.

- Drawings - Help you detail your designs faster with improved workflows and time saving automation. Open sub-component drawings from within an assembly drawing.

- SOLIDWORKS Visualize - Achieve stunning visuals with less effort thanks to streamlined import options, expanded color management capabilities, and an all-new rendering engine. See how your lifeless CAD model into engaging visuals faster than ever before..

Laser Cutting

Regardless of the quantity, single pieces , small or large series, laser cutting is the preferred method for manufacturing sheet metal parts. It offers exceptional accuracy, excellent cut quality, and very high productivity.

The two main types of laser cutting systems are solid-state (LPSS / DPSS / Fiber) and gas laser (CO2). Our laser cutting partners have both, which allows us to sell all ferrous and non-ferrous metals and a wide range of non-metals. With our commitment to using top-of-the-line laser cutting technology and partnering with the best providers in the industry, EstNor Steel ensures that your project will be manufactured with the highest precision and quality.

- Up to 25 mm Thick Material- 8 and 10 kW lasers can punch through steel, stainless, and aluminum up to 25 mm thick, with the remarkable cut quality and minimal burr. In thick metals especially, cut quality depends significantly on heat buildup. Our machines help keep thick material cool by applying water cooling during the cut, and pierce splash-out is mitigated by spraying the material with a small amount of oil during the pierce.

- Unrivaled Aluminum Quality-Aluminum is usually difficult to cut cleanly on a fiber laser. We've used the latest cutting technology to almost completely eliminate cutting burr on aluminum up to 1" thick.

- Precision Blank Cutting-Our fiber lasers produce blanks within +/- 0.005" accuracy and ultra-high precision, with minimal to non-existent taper even in thick plate. Order your parts knowing that you'll receive consistent, precise performance on every part, every time.

Sheet Bending

Bending is one of the sheet metal industry’s most commonly used machining methods. The two keywords regarding sheet metal bending are accuracy and quality. EstNor Steel can guarantee both, thanks to the latest generation of digital hydraulic press brakes.

- Precision Bending- With precision back-gauge positioning to within +/- 0.025 mm real-time material thickness measurement and compensation, and high precision ram placement, our equipment can produce parts with a high degree of accuracy and repeatability. Our standard bend angle tolerances are +/- 1.0 degree.

- Clear Communication, Instant Feedback- Designing parts for precision bending can be complicated. In bending, radius, k-factor, and part geometry are limited by your shop's tooling and material. As a result, finalizing a design often requires a lengthy back-and-forth with the shop, increasing costs and lead times.

- 3D Model Support- Our automated quoting engine supports your native 3D models, accepting common file formats including STEP, SLDPRT, CATPART, IPT, PAR, and IGES.

- 2D Flat Patterns- Don't have a 3D model? No problem! We can take your 2D flat pattern in DXF format and show you a 3D model of your finished part. Your flat pattern just needs to contain punch lines to indicate where you'd like us to place the punch during bending.

- Our highly skilled -technicians have the expertise to handle even the most complex bending projects, and we take pride in offering a wide range of bending services to meet our client’s diverse needs.

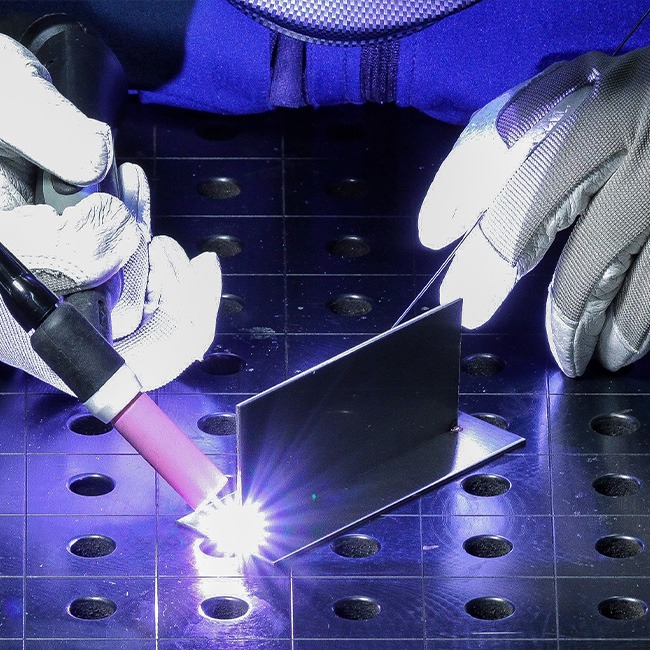

Welding

EstNor Steel can offer all types of ferrous and non-ferrous metal weldings. We have welding expertise at the very top level, and we deliver certified welding according to national and international requirements. Our team of experienced welders is focused on quality production processes. You can depend on our expertise when you need custom metal welding and reliable results. Quality work must be carried out by certified personnel. Our partner has its welding engineers (IWE and IWT) trained according to IIW (International Institute of Welding).

- Robotic Welding- Robotic welding stations are used when customers need higher quality welds or a high volume of welds. When exacting repeated welds are needed, Weld Technologies offers automated welding. Using robotics to weld components creates cost savings through a reduction in labor costs and an increase in the number of parts produced per hour. Robotic welded parts also dramatically increase the quality of the parts produced.

- Manual Welding MIG, TIG- EstNor Steel has several manual welding cells. MIG welding uses a wire which is fed through the MIG gun, providing a continuous stream of binding material. TIG welding is optimal for projects that require precision. This type of arc welding uses a non-consumable tungsten electrode to produce precise clean welds. TIG welds are better for thinner metals and smaller projects.

- Resistance Welding- Resistance welding is useful for its speed, simplicity, and consistency. It is an attractive solution, because of its high production rates. This welding process is used for a wide range of automotive and industrial applications

- Welding Stainless Steel and Aluminum- EstNor Steel combines the latest technology with our extensive experience to deliver high-quality welded components. We offer welding services with a comprehensive range of materials, including; stainless steel and aluminum.

Hot dip galvanizing

At the customer’s request, we can have it done with zinc coating . The zinc coating is relatively thin, 70–100 µm, which is the optimum method for protecting steel against corrosion. Galvanized parts do not require maintenance in a typical environment for about 50 years.

- EstNor Steel understands the importance of protecting your steel products against corrosion, which is why we offer zinc coating at the customer's request to provide an effective and durable layer of protection.

- With a relatively thin coating of 70-100 µm, zinc coating is the optimum method for ensuring long-lasting protection against corrosion, and can provide maintenance-free protection for up to 50 years in typical environments.

- Our team is committed to providing our clients with the best possible protection for their products, and we use only the highest quality zinc coating materials to ensure that your steel products are safeguarded against corrosion for years to come.

Powder Coating

In the color selection, we have RAL and RR shades. As a standard, we cover the paintable surfaces of the parts with a layer of powder paint with a thickness of 70+/-5 microns, in other cases, it is a matter of special agreement.

- EstNor Steel understands that the appearance of your products is just as important as their functionality, which is why we offer a range of color options to meet your specific requirements.

- Our team utilizes industry-leading RAL and RR shades to provide a wide variety of color options that can be customized to your exact needs, ensuring that your products look exactly as you envisioned.

- With a standard layer of powder paint that covers the paintable surfaces of parts with a thickness of 70+/-5 microns, we provide a durable and long-lasting finish that will enhance the appearance of your products and protect them against wear and tear. In cases where special requirements are necessary, we are always willing to work with our clients to ensure that their needs are met to the highest standards.